Eckerts Wacholder Brennerei GmbH is a German distillery that blends long-standing craftsmanship with fashionable manufacturing strategies. To enhance packaging effectivity, the corporate applied Robotiq Lean Palletizing. This automation venture elevated throughput, improved security, and diminished the handbook workload—all with out disrupting the distillery’s conventional processes.

The problem: Heavy cartons, weak containers, and restricted area

Eckerts produces and ships a variety of spirits. The top-of-line palletizing course of created a number of bottlenecks:

- Heavy cartons (as much as 8 kg every) slowed down handbook dealing with.

- Structurally weak containers required mild, constant placement.

- A compact workshop made it troublesome to put in totally enclosed methods.

- Security considerations arose as a result of workers wanted to work near the robotic.

- Coaching time for brand spanking new know-how needed to stay minimal to keep away from disruptions.

The group wished automation that improved effectivity whereas defending each product high quality and worker well-being.

Why Eckerts chosen Robotiq

To validate the answer, Eckerts despatched its heaviest cartons to Robotiq’s Lyon workplace. The palletizer efficiently dealt with each field sort, demonstrating its functionality earlier than set up.

Key attributes that supported the choice:

- Open, enclosure-free structure that match the distillery’s restricted ground area.

- Built-in security options that cease the robotic mechanically when folks strategy.

- Quick onboarding, permitting workers to make use of the system confidently after in the future of coaching.

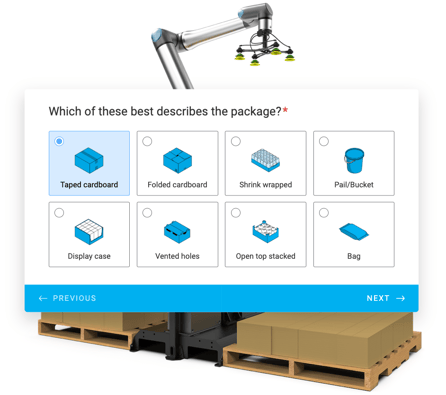

- Compatibility with 15 totally different carton varieties, lowering changeover effort.

“This answer is likely one of the greatest issues we’ve got purchased lately. The system has been working flawlessly from day one.”

– Manufacturing Supervisor Andreas Klemp

The answer: Robotiq Lean Palletizing

Robotiq Lean Palletizing supplied the next capabilities:

- Excessive throughput, supporting as much as 500 cartons per hour.

- Exact dealing with, perfect for fragile or weaker cardboard buildings.

- Protected human-robot interplay, suited to small manufacturing areas.

- Consumer-friendly software program that simplifies setup and operation.

The system’s design allowed Eckerts to automate palletizing whereas preserving the workflow of a standard distillery setting.

Outcomes: Effectivity, security, and sooner operations

After implementing the Robotiq answer, Eckerts noticed a number of enhancements:

1. Elevated effectivity

The palletizer dealt with heavy masses persistently, lowering handbook lifting and bettering general throughput.

2. Decrease labor prices

Operators may shift from repetitive duties to higher-value obligations in manufacturing.

3. Safer working circumstances

Constructed-in security options maintained a safe setting, even inside a compact workspace.

4. Fast worker adoption

Coaching required solely in the future, lowering downtime and enabling fast use.

The impression: Custom supported by fashionable automation

Eckerts’ expertise demonstrates how automation can combine seamlessly right into a heritage-focused business. Robotiq Lean Palletizing helped the distillery:

- Preserve product high quality

- Scale back bodily pressure

- Enhance manufacturing stability

- Help long-term operational sustainability

Automation turned a technique to shield craftsmanship, not change it.

Discover Lean Palletizing for your self

Producers dealing with heavy masses, blended packaging, or workforce constraints can profit from the identical dependable and secure automation system used at Eckerts.

If you wish to see whether or not palletizing automation is sensible to your facility, begin with the Palletizing Match Software — a fast, interactive technique to see if Lean Palletizing is the appropriate match to your line.

Need extra tales from actual factories like yours?

Comply with Robotiq on LinkedIn and be a part of over 75,000 producers seeing how automation retains folks secure, and manufacturing working sturdy.