Background and Buyer Wants

Our shopper, a widely known electronics producer in Taiwan, makes a speciality of high-volume server manufacturing. Within the remaining stage earlier than cargo, each unit should bear visible inspection to confirm the presence, positioning, and situation of key elements—akin to connectors, cable ties, caps, battery, cable routing, SSDs, and screws.

Beforehand, this course of relied closely on guide inspection, which was not solely time-consuming but in addition inconsistent on account of employee fatigue. The growing complexity of server configurations additional amplified the chance of undetected defects, high quality variations, and dear rework.

The client required a dependable and scalable inspection system that might:

- Carry out constant visible checks throughout a number of element sorts

- Cut back human error and inspection time

- Guarantee secure high quality earlier than supply

Challenges

Though SOPs had been in place, the guide inspection course of confronted the next key challenges:

- Fatigue-related errors: Human inspectors usually missed delicate points, particularly throughout lengthy shifts.

- Lack of consistency: Judgment diversified between operators, impacting high quality stability.

- Non-traceable course of: No systematic methodology existed to file or hint inspection outcomes.

- Complexity of elements: The wide selection of components and configurations made visible checking troublesome to standardize.

These points underscore the necessity for an automatic resolution that might guarantee repeatable accuracy and cut back dependence on guide labor.

Resolution

To enhance inspection efficiency, the producer applied a robotic arm resolution utilizing the TM AI Cobot, which is built-in with a built-in imaginative and prescient system, and a strong software program known as TM AI+ Coach.

Inspection Course of:

- The AI mannequin was educated utilizing picture datasets labeled as “OK” and “NG” based mostly on a number of server element samples.

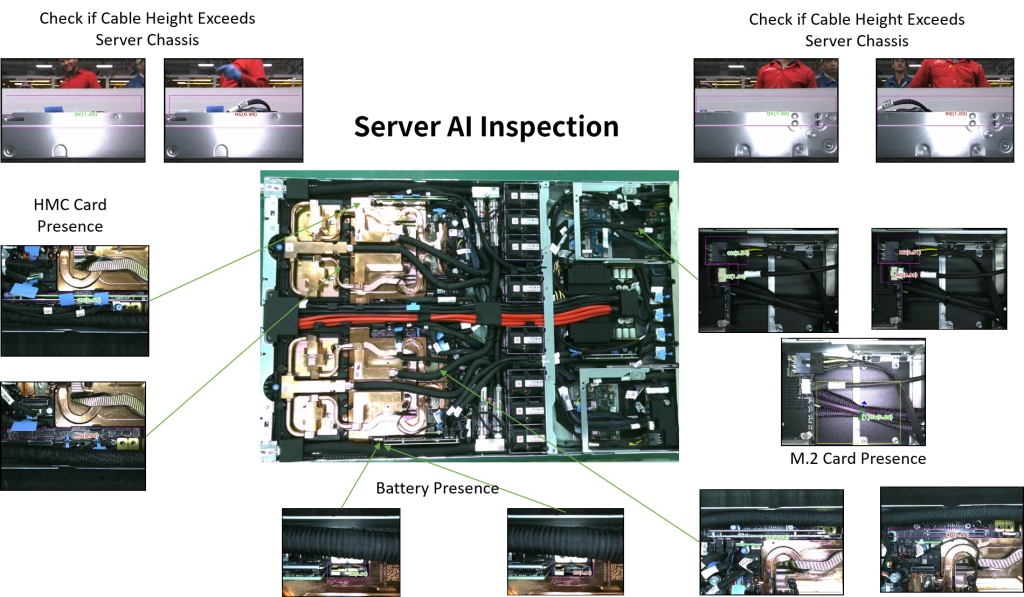

- After capturing a picture of the server, the AI mannequin classifies every space (e.g., connector, battery, cable tie) to find out whether or not the half is current, right, or irregular.

- If an abnormality (NG) is detected, the system instantly flags the unit and removes it from the road for additional dealing with.

Key Inspection Targets:

- Connector, cap, and cable tie detection

- Battery presence and cable routing

- SSD and screw presence verification

AI Mannequin Coaching

- AI Perform Used: Classification

- Information Supply: Labeled photos captured instantly from manufacturing

- Coaching Methodology: Commonplace supervised coaching with categorized picture units

Outcomes & Advantages

- Parallel multi-point detection: Simultaneous inspection of a number of components decreased cycle time

- Greater consistency: AI supplied uniform inspection judgment no matter shift or operator

- Improved traceability: All inspection outcomes had been recorded digitally for monitoring and QA evaluation

- Decreased rework and after-sales danger: Solely certified servers proceed to cargo

Conclusion

With TM AI Cobot as an automatic inspection resolution, the shopper efficiently changed time-intensive guide checks with a dependable AI-powered system. This not solely enhanced inspection effectivity and traceability but in addition ensured increased product high quality on the remaining stage—reinforcing belief within the firm’s server manufacturing excellence.