For years, machining laborious metals has been a big problem for manufacturing automation. With new robotic machining methods, machining laborious supplies is now potential.

Hardened metal, tempered metal, titanium, and different high-strength supplies are important in industries like aerospace, automotive, and power.

Nevertheless, the very power that makes these supplies helpful additionally presents an issue for automation. Historically, they might solely be dealt with by specialist, inflexible CNC machines — a machining robotic would haven’t any probability!

However, that is altering…

On this article, we’ll discover how new high-stiffness robots are redefining what is feasible with robotic machining. We’ll cowl what makes sure supplies tough to chop and the way robots are actually assembly the problem.

Step one to really understanding the potential of robotic machining is to grasp the supplies themselves.

Machinability is a measure of how simply a cloth might be reduce. It is dependent upon a steadiness of properties together with hardness, ductility, toughness, and thermal conductivity.

Some supplies are famously simple to work with, reminiscent of aluminum. Others are so laborious, heat-resistant, or abrasive that even a small undertaking can put on via tooling or destabilize a machining setup.

Simple to Machine Metals

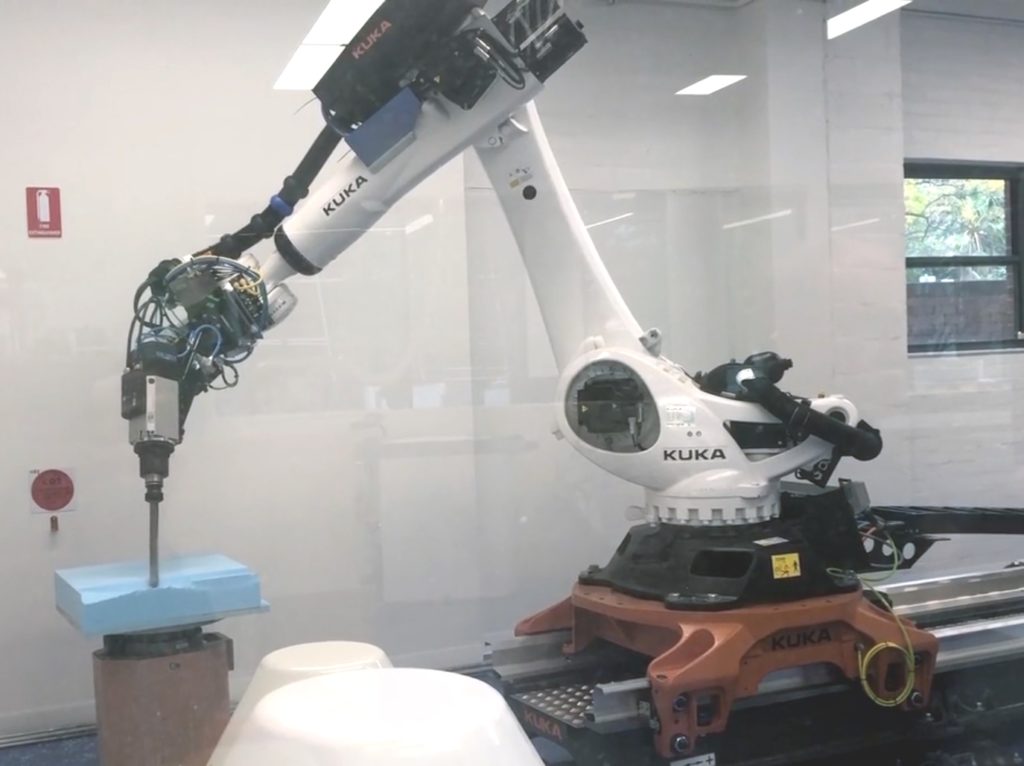

Previously, robotic machining was solely sturdy for delicate, easy-to-machine supplies as a result of compliance of commercial robotic joints.

Examples of “pleasant” metals which might be simple to machine embrace:

- Aluminum — This stalwart of producing is well-known for its wonderful thermal conductivity and ease of chopping.

- Delicate metal — That is sturdy sufficient for construction, however nonetheless manageable for machining.

- Brass Utilized in fewer tasks than the earlier two, this presents predictable chip formation and minimal device put on.

Onerous to Machine Metals

Newer robotic machining methods — reminiscent of these from Autonox that we noticed at Automatica 2025 — are actually able to machining more durable supplies that have been beforehand unimaginable.

Examples of laborious to machine metals embrace:

- Hardened and tempered metal — These steels are handled to withstand deformation, placing extra pressure on chopping instruments and thus requiring stiffer machining instruments.

- Titanium alloys — These are prized for his or her strength-to-weight ratio however infamous for poor warmth dissipation.

- Inconel and nickel-based superalloys — These specialist and typically proprietary supplies can retain their hardness even at red-hot temperatures.

Whereas robotic machining remains to be restricted with these supplies, the brand new methods from Autonox that may machine tempered metal, mark a change. Robotic machining is now a viable choice for machining laborious metals.

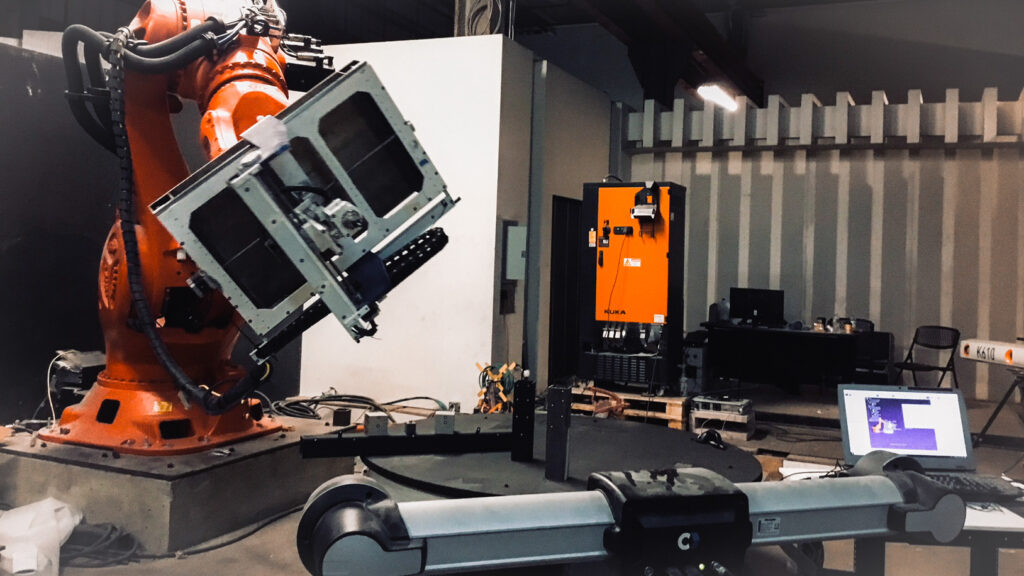

The Increasing Position of Robots in Industrial Machining

At RoboDK, we now have been following the event of robotic machining for years. Our main robotic programming software program is utilized by many producers trying to make their processes extra versatile with robotics, together with for machining functions.

Robots provide extra advantages for machining, together with help for bigger workspaces, extra complicated geometries, and better flexibility for manufacturing circulate adjustments.

Lately, a brand new technology of high-stiffness industrial robots has created a shift in industrial machining. Operations that beforehand would solely have been potential with a traditional CNC machine are actually achievable with robots.

A number of elements are driving this growth together with:

- Improved mechanical stiffness of robotic manipulators.

- Dynamic compensation of vibrations in robotic controllers and management software program.

- Precision calibration of robotic manipulators.

- Excessive-precision encoders that enable for extra correct joint management and secure chopping paths.

- Robotic programming instruments for robotic machining like our [set of free add-ons for optimizing applications][ADDON] like robotic machining.

This mixture of things permits robots to deal with more durable supplies with better accuracy and management than ever earlier than. Whereas nonetheless much less inflexible than standard CNC machines, the hole between the applied sciences is decreasing.

The Downside: Managing the Forces Behind Onerous-Materials Machining

The foremost problem when machining laborious supplies is managing the extraordinary forces on the machining device.

In easy phrases, because the robotic’s machining device pushes down on the fabric, the fabric pushes again with an equal pressure. Even a small quantity of compliance within the robotic mechanism may cause vibrations, resulting in machining inaccuracies.

There are two methods for managing these vibrations:

- Passive: Robotic Mechanism Design — The brand new wave of commercial robots is being designed with high-stiffness mechanical buildings that may stand up to excessive forces.

- Lively: Management and Programming — Each low-level joint management and high-level programming mix to actively counteract vibrations after they happen.

A robotic system appropriate for machining laborious supplies will mix each methods to make sure correct machining.

What steps can you’re taking to enhance the accuracy of your robotic machining system?

One issue that folks often overlook is calibration.

When programming a robotic to machine laborious metals, even the smallest inaccuracy in a robotic’s kinematic mannequin can translate into seen floor errors. That is the place robotic calibration turns into the key weapon.

Calibration entails figuring out and correcting geometric deviations between the robotic’s digital mannequin and its real-world habits. By aligning these parameters, you make sure the device follows the supposed path with most precision — an important step when tolerances are tight and supplies are unforgiving.

We provide a spread of Robotic Calibration options to assist guarantee your robots carry out at their very best.

Robotic Machining: Redefining What’s Attainable With Onerous Supplies

The flexibility to machine hardened metals with robots marks a defining second in industrial automation. What was as soon as thought-about the area of solely essentially the most inflexible CNC machines is now more and more potential with robots.

By combining the most recent wave of high-stiffness robotic mechanisms with the fitting programming instruments, robotic calibration, and superior simulation, you’ll be able to profit from the pliability and scalability that robotic methods provide.

Which difficult supplies would you prefer to machine with a robotic? Be a part of the dialogue on LinkedIn, Twitter, Fb, Instagram, or in the RoboDK Discussion board.. Additionally, take a look at our intensive video assortment and subscribe to the RoboDK YouTube Channel