With its distinctive, glossy white branding and sunshine-orange robots, Stäubli is a key participant within the robotics trade. However what’s the easiest way to program Stäubli robots?

From high-speed SCARA robots — just like the TP80 — to compact 6-axis arms — just like the RX60 — Stäubli robots are a stalwart of many manufacturing environments. This Swiss-based producer has been increasing globally ever since its beginnings as a weaving know-how pioneer in 1892.

On this important information, we’ll discover what makes Stäubli robots distinctive and clarify the completely different choices for programming them simply and effectively.

Who Are Stäubli?

Based in 1892 in Switzerland, the Stäubli Group started as a producer of weaving machines. At first, the corporate step by step added new applied sciences to their textile machines, from fast couplings to pneumatics and hydraulics.

It wasn’t till virtually a century later, in 1982, that robotics entered the corporate’s catalog. Starting with their distinctive SCARA robots, this marked a key shift in the direction of being the robotics firm that we all know immediately.

Over 130 years, the corporate has regularly pushed the boundaries of automation know-how. Their core purpose is to develop options for secure, simple to deploy industrial processes.

Stäubli robots at the moment are utilized in many industries, however the firm maintains sturdy hyperlinks to the textile trade.

The place Stäubli Robots Excel: Excessive-Precision Industrial Purposes

The corporate’s robots are acknowledged globally for his or her excessive precision and reliability. Stäubli’s deal with mechanical high quality and built-in management permits its robots to carry out with excessive accuracy throughout industries.#

Just a few of the huge vary of widespread Stäubli purposes embody:

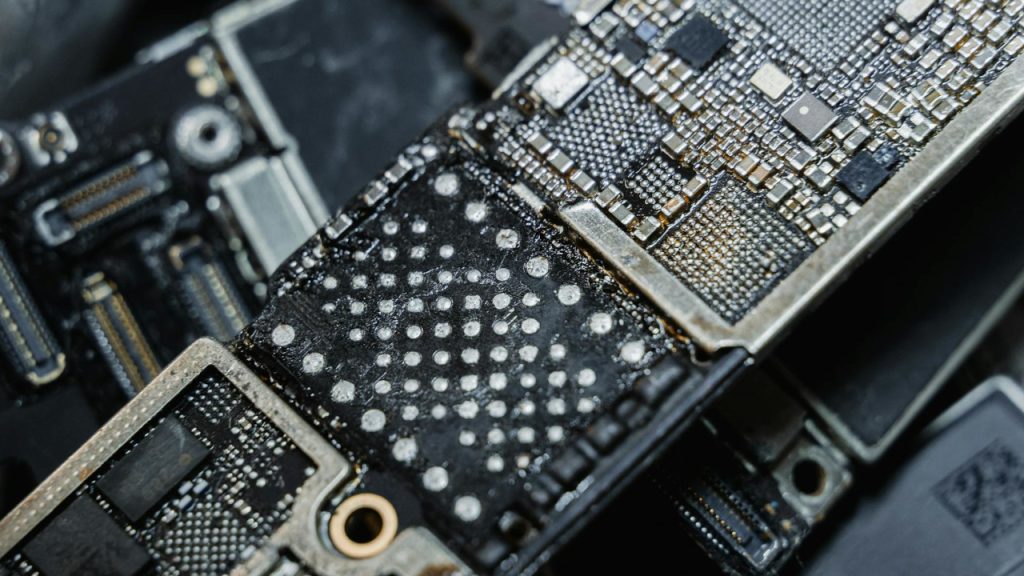

- Electronics and Semiconductor Manufacturing — Robots just like the distinctive Stäubli SCARA robots deal with delicate parts in cleanrooms.

- Pharmaceutical and Medical Machine Manufacturing — With the corporate’s [specialism in robots for sterile environments][STERI], they’re usually utilized in pharmaceutical settings.

- Automotive and Aerospace — Performing small-parts meeting, gluing, and testing operations, Stäubli robots are used for a variety of duties throughout the automotive trade.

No matter your trade, it’s possible that there are Stäubli fashions which can be completely suited to your utility and wishes.

Programming Stäubli Robots: The three Core Choices

There are a number of methods to program a Stäubli robotic, every suited to completely different ranges of programming experience and expertise.

Let’s discover the three most typical choices for programming the corporate’s robots:

1. VAL3 Programming Language

Like most industrial robotic producers, Stäubli has its personal proprietary programming language that’s used within the firm’s Robotics Suite software program.

VAL3 is a devoted robotic programming language that extends from its predecessor VAL II. Relatively confusingly, it is unrelated to Variable Meeting Language (VAL), a programming language from the Seventies.

If you’re an skilled programmer with a must program your robotic at a low-level, it’d make sense to study VAL3.

2. Educate Pendant Programming

A robotic’s educate pendant is the standard route for programming industrial robots. Stäubli’s vary of educate pendants contains each graphical and text-based programming choices.

Though educate pendants are perfect for making minor changes, all of them undergo from a typical subject. You could take your robotic out of manufacturing to vary the programming — this results in delays and may waste invaluable time that the robotic could possibly be working.

3. RoboDK: Offline Programming for Stäubli Robots

RoboDK gives an intuitive and highly effective technique to program Stäubli robots with out interrupting manufacturing.

With RoboDK, you possibly can program, simulate, and optimize your robotic applications inside a graphical simulator atmosphere. You may then use offline programming to ship this system on to your Stäubli robotic and even management the robotic in actual time.

By integrating RoboDK into your setup, you achieve:

- CAD/CAM Integration — Our CAD/CAM plugins permit you to import instrument paths straight out of your most popular design software program and export them on to your Stäubli robotic.

- Offline Simulation — By simulation, you possibly can validate trajectories, check the robotic for reachability, and keep away from pricey collisions.

- Calibration and Toolpath Optimization — RoboDK’s in-built calibration options permit you to fine-tune your paths for purposes like precision machining, inspection, and pick-and-place.

Highlight on 3 Stäubli Robots within the RoboDK Library

Our in depth Robotic Library incorporates over 1,200 industrial robots from 80+ manufacturers, together with dozens of fashions from Stäubli.

Listed below are three Stäubli robots featured within the RoboDK library:

1. Stäubli TX90

The Stäubli TX90 is a 6-axis robotic with a 6 kg payload and 900 mm attain. It contains IP65 ingress safety, compatibility with sterile environments, and even is available in customizable colours.

The manipulator gives glorious repeatability (±0.03 mm) and is ideal for precision machining, testing, and inspection purposes.

2. Stäubli RX60

The Stäubli RX60B and RX60BL are versatile robots which can be usually discovered refurbished. They are perfect for duties like meeting, materials dealing with, and allotting.

These two comparable fashions differ in that there’s a trade-off between attain and payload capability. The RX60B has a attain of 600 mm and a payload capability of three.5 kg, whereas the RX60BL has an extended attain of 800 mm however a smaller payload capability of two.5 kg.

3. Stäubli TP80

The Stäubli TP80 is without doubt one of the quickest SCARA robots on the earth. It’s usually used within the medical manufacturing trade and was instrumental within the manufacturing of Covid-19 testing through the 2020 international pandemic.

Able to over 200 picks per minute, its light-weight design and cleanroom variants make it ultimate for high-speed packaging and pharmaceutical strains.

Getting Began with RoboDK for Stäubli Robots

When you’re prepared to start out programming your Stäubli robotic, right here’s easy methods to start with RoboDK:

- Obtain RoboDK and set up it in your laptop.

- Seek for your Stäubli mannequin within the Robotic Library.

- Load the mannequin into RoboDK, create your path, and simulate your course of.

- Export your program in VAL3 format and deploy it to your controller.

With its highly effective simulation and post-processing instruments, RoboDK lets you go from idea to manufacturing quicker whereas sustaining Stäubli’s world-class requirements for precision and reliability.

Which Stäubli robotic are you programming? Be part of the dialogue on LinkedIn, Twitter, Fb, Instagram, or in the RoboDK Discussion board.. Additionally, take a look at our in depth video assortment and subscribe to the RoboDK YouTube Channel