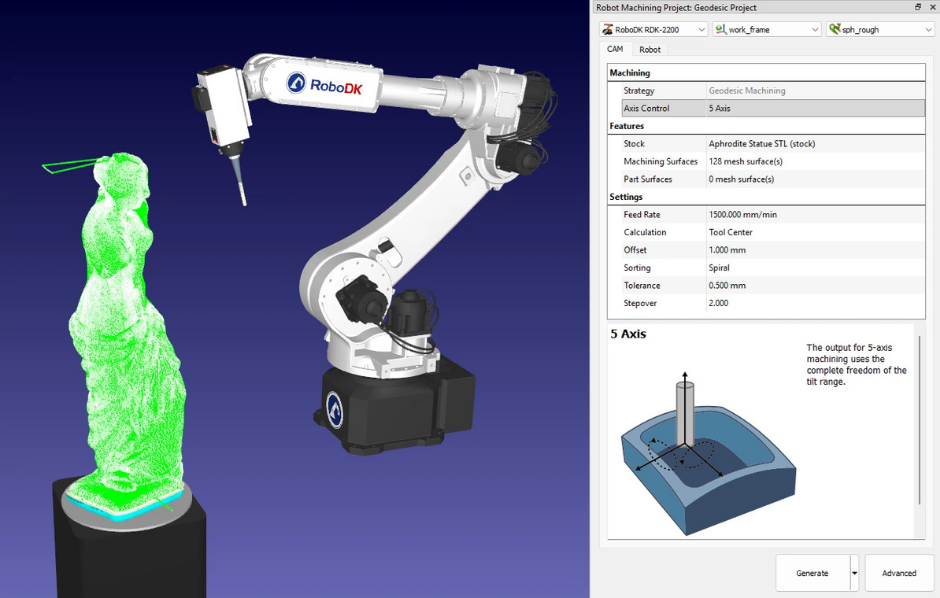

RoboDK has launched a CAM resolution designed to slash deployment instances for machining automation by eliminating conventional, guide programming necessities. RoboDK CAM’s options embrace multi-axis machining, collision detection, toolpath technology, and machine simulation. It additionally reduces deployment instances considerably for automated machining cells.

Not like advanced conventional approaches which require specialists to manually program every robotic and end-effector utilizing vendor-specific languages, RoboDK CAM routinely generates robotic code from CAD designs and digital simulations, decreasing the complexity and value of machining automation deployments. This enables producers and integrators to maneuver immediately from design to manufacturing with out having to be specialists in robotic programming.

CAM Functions

RoboDK CAM helps a variety of machining operations, together with milling, drilling, deburring, slicing, and additive manufacturing. Customers can generate superior toolpaths, simulate full machining processes, detect collisions, and transition from easy 3-axis duties to 5-axis machining inside a single, intuitive setting. Moreover, as an alternative of getting to spend weeks testing and programming numerous configurations of your machining cell, RoboDK CAM lets you take a look at your setup in a protected, simulated setting in minutes.

RoboDK CAM Configurations

The brand new software program is out there in two configurations, addressing completely different manufacturing workflows:

- Standalone: RoboDK CAM permits customers to handle the whole robotic machining course of—from toolpath technology to robotic simulation and code technology—inside one built-in interface. Key capabilities embrace superior floor machining, correct inventory monitoring, and full machining simulation.

- Built-in: designed for machining professionals who need to work inside established CAD/CAM platforms. RoboDK CAM integrates with all main programs corresponding to Fusion 360, SolidWorks or Mastercam by means of devoted Add-ins, enabling customers to retain their present CAM workflow whereas extending it to industrial robots utilizing RoboDK’s simulation and programming engine.

Usually, it takes weeks of testing and programming to deploy machining automation, however as early testers of the software program have reported, RoboDK CAM reduces testing time considerably -up to 40% relying on the complexity of the automation- and cuts general deployment instances from days to only minutes.

“RoboDK CAM is a milestone software program launch that eliminates the complexity related to programming robots to carry out machining duties, Automation drives effectivity, however advanced programming and multi-vendor system integration troubles have been severe roadblocks for firms trying to undertake robots. RoboDK CAM addresses these challenges immediately,” stated Albert Nubiola, CEO, RoboDK.

For producers, RoboDK CAM permits sooner automation rollouts, diminished downtime, and faster iteration on machining processes. For system integrators, the software program shortens challenge timelines and reduces the engineering effort required to deploy robotic machining cells.

“RoboDK CAM makes it simpler for producers to undertake robotic machining with out overhauling their present processes,” stated Sergei Kanivets, Utility Engineer at RoboDK. “As a result of it’s constructed on the RoboDK platform, we are able to ship an entire CAM resolution at a considerably decrease price than conventional alternate options.”

“RoboDK exists to democratize automation for individuals of all technical talent ranges and corporations of all sizes. We plan to maintain including new merchandise and options like RoboDK CAM which might be designed to make automation simpler than ever to deploy -even in superior manufacturing functions,” provides Albert Nubiola, RoboDK’s CEO.

Prepared to find RoboDK’s superior CAM integration for next-generation robotic manufacturing? You’ll be able to study extra about RoboDK CAM in RoboDK web site, or contact the workforce for additional questions.