What’s Welding Automation?

Welding automation leverages programmable robotic methods and superior controls to execute welding duties with minimal human enter, making certain constant weld high quality and elevated manufacturing effectivity. Semi-automated methods want operators to load and unload whereas the robotic performs the weld. Absolutely automated setups handle the whole course of, together with inspection. Such automation can almost triple productiveness in comparison with guide welding for 80% arc-on time versus 30% for people.

Automotive and aerospace industries profit from such methods. The worldwide welding automation market could attain $16.87 billion by 2030. But, implementing them entails capital funding from $50,000 to $150,000 and expert personnel for programming and maintenance. Regardless of the value, welding automation is important to up to date trade on account of its precision and efficacy.

Advantages of Welding Automation

Elevated Productiveness

With welding automation, cycle occasions shrink. A single robotic MIG station may produce round 60 inches of weld per minute. It helps eradicate guide pauses for repositioning. Furthermore, programmable fixtures reduce idle time. Many methods use servo-driven wire feeders, which preserve pressure and reduce burn-back. Excessive-speed digital camera monitoring additionally optimizes torch angles in real-time. The result’s a far greater output quantity with minimal downtime.

Improved High quality

Welding automation ensures repeatable weld profiles with negligible spatter. Upgraded sensors observe arc stability and proper for voltage fluctuations on the fly. Built-in real-time weld analytics measure penetration depth and wire feed velocity. It helps circumvent porosity and undercut points. Constructed-in closed-loop suggestions methods spot misalignment and modify torch place. Uniform weld beads emerge with out guesswork on complicated multi-pass jobs.

Value Financial savings

Labor bills drop as fewer expert operators are wanted for repetitive duties. One operator can oversee a number of cells as an alternative of tackling every weld manually. Much less filler metallic is wasted as a result of automated parameters are actual. Decrease warmth distortion means fewer rework steps. Many producers recoup their funding inside 1-3 years. When contemplating downtime reductions, welding automation is remarkably extra worthwhile in the long term.

V2A057EN TM AI Cobot – What Are the Advantages of Welding with Cobots ft. HiWeld

Key Elements of Welding Automation Methods

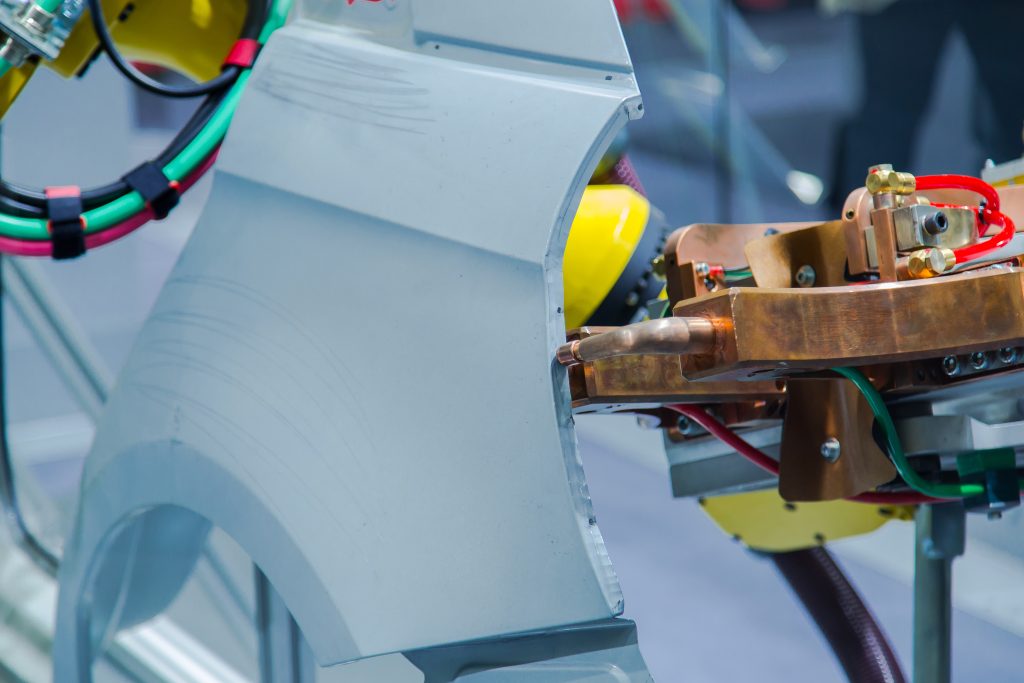

Welding Robots

Welding robots can execute multi-axis actions that preserve torch orientation inside fractions of a level. They combine servo-driven wire feeders and pulse-width modulation to control warmth enter on thin-gauge metals. Moreover, they’ve offline programming, which simulates joint paths and collision factors earlier than reside manufacturing. Many fashions use inertia compensation algorithms to stabilize long-reach arms and reduce weld distortion. Such traits render them important to welding automation in repeatable industries.

Positioners and Manipulators

Positioners and manipulators modify the weld angle whereas rotating, tilting, or indexing workpieces with actual increments. Tilt-rotate positioners permit 360-degree entry to circumferential seams for decrease re-clamping errors. Many methods incorporate robotic monitoring that synchronizes desk motion with the robotic’s arc place. Excessive-torque servo motors protect secure holding forces for giant assemblies with off-center mass distribution. Their stability and precision are key to welding automation since half geometry could be complicated.

Sensors and Controllers

Welding experience will likely be wanted sooner or later: 360,000 extra welders are required by 2027; 90,000 are wanted yearly between 2023 and 2027; and over 155,000 welders are nearing retirement. So, automation sensors and controls are key to boosting productiveness and tackling labor shortages. Sensors monitor weld pool profiles, arc voltages, and wire feed pressure. Laser seam monitoring or through-arc sensing adjusts the torch place on the fly. It compensates for hole variations or half misalignment. Controllers course of such inputs at millisecond intervals and replace movement instructions. Some methods log thermal enter and weld bead information for post-weld evaluation. Suggestions loops enhance welding automation through decreased faults and elevated output.

Software program and Programming

Welding software program combines CAD information and robotic kinematics for path planning and collision avoidance. Quick kernels run path interpolation that reacts to sensor suggestions in microseconds. Many options supply automated parameter optimization to regulate present and journey velocity for every weld go. Simulation instruments can foresee distortion on giant fixtures and assist engineers fine-tune clamp placements. Such software program methods velocity up manufacturing and supply exhaustive customization as welding automation’s digital spine.

Functions Throughout Industries

Manufacturing – Basic Industrial Use Instances

Typically manufacturing, robotic welding cells add instantaneous seam monitoring, adaptive energy controls, and multi-axis movement for complicated geometries. Excessive-precision sensors measure arc stability and penetration depth. The information feeds into controllers that modify the torch place. It eliminates rework and reduces heat-affected zones. Welding automation advantages high-volume fabrication of heavy tools frames, stress vessels, and structural elements.

Automotive – Automobile Meeting Traces and Element Welding

In automotive manufacturing, multi-robot stations execute synchronized spot, MIG, and laser welding on chassis and physique assemblies. Compact robotic arms with servo-driven weld weapons assure constant electrode drive throughout quite a few welds per shift. Automated imaginative and prescient methods acknowledge misalignments and immediately refine weld parameters. Such an instantaneous correction precludes metallic fatigue in necessary zones. Welding automation additionally offers with supplies, together with ultra-high-strength metal and aluminum alloys, with high quality tolerances.

Aerospace and Protection – Precision Welding and Security-Essential Operations

Friction stirs and electron beam welding in aerospace and protection want temperature gradient management. Automated gantries observe seams to fractions of a millimeter for reliable penetration and microstructure. Welding automation helps produce rocket engine nozzles, fuselage joints, and turbine elements that bear thrilling situations. Each weld go is logged for post-process evaluation for high-stakes mission security. Bear in mind, the worldwide aerospace welding machines market could broaden by 4.2% from $1.385 billion in 2025 to $1.924 billion in 2033.

Able to elevate your welding operations? Uncover how TM AI Cobot delivers unmatched high quality, effectivity, and ROI. Contact us immediately for a personalized automation resolution.