Stroll by way of a contemporary plant in 2026 and also you’ll discover one thing vital: automation isn’t displaying up solely within the “high-tech” corners anymore. It’s touchdown the place it creates the quickest, most dependable worth — particularly within the elements of the manufacturing unit that was left behind as a result of they had been too variable, too guide, or too laborious to justify.

Throughout surveys and what we see on actual flooring, the sample is evident: producers are prioritizing automation that helps them stabilize output, shield individuals, and keep versatile below uncertainty. Persistent labor shortages and expertise gaps are nonetheless the backdrop, so the “why” isn’t mysterious; it’s operational survival and aggressive benefit. (Deloitte)

Right here’s the place automation is concentrating in 2026, and the explanations behind every transfer.

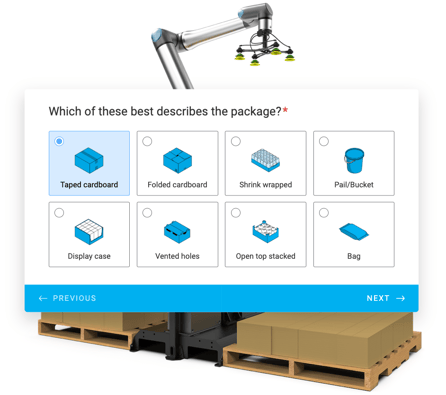

What’s getting automated: palletizing, depalletizing, case dealing with, stretch wrapping, and different end-of-line duties.

Why in 2026:

- Labor reduction the place the ache is fixed. Finish-of-line roles are bodily demanding and laborious to employees persistently. With expert labor shortages nonetheless acute, these stations are prime targets for robotics. (Deloitte)

- Clear ROI and quick time-to-value. These purposes have measurable throughput and security good points, making the enterprise case simpler than many upstream processes.

- Flexibility is lastly adequate. Vegetation need automation that may deal with SKU churn and seasonal peaks. “Hyper-flexible” manufacturing — methods that may be reconfigured shortly — is a defining shift proper now. (The Financial Instances)

Robotiq lens: Finish-of-line is commonly the first automation step as a result of it’s the cleanest win: secure course of, seen influence, and low disruption to upstream manufacturing.

What’s getting automated: AMRs/AGVs for shifting pallets, totes, and WIP; automated line feeding; buffer administration.

Why in 2026:

- Circulation beats pace. Producers are realizing that inside transport bottlenecks quietly kill OEE. Automating motion creates smoother stream with out redesigning the entire plant.

- Simpler to scale than mounted conveyors. Cell robotics aligns with the shift to modular, software-defined factories the place layouts change extra typically. (The Financial Instances)

Security + predictability. Automated transport reduces forklift site visitors and “last-minute heroics.”

What’s getting automated: imaginative and prescient inspection, in-process measurement, AI-assisted defect detection.

Why in 2026:

- High quality is a high digital funding space. Surveys present high quality administration and AI-enabled inspection sit close to the highest of producers’ smart-tech spend. (Rockwell Automation)

- AI makes variability manageable. Trendy imaginative and prescient + ML handles imperfect real-world variation higher than conventional rules-based QC.

Scrap prices are too excessive to disregard. Catching points earlier has a compounding impact on yield and scheduling reliability.

4. Machine tending and repetitive manufacturing duties

What’s getting automated: CNC/press tending, loading/unloading, easy pick-and-place, packaging steps, secondary ops.

Why in 2026:

- Excessive repeatability = fast wins. These duties are secure, straightforward to standardize, and supreme for cobots and compact cells.

- Getting older expert trades hole. The scarcity isn’t simply basic labor; it’s skilled operators and technicians. Automation helps maintain machines operating even when staffing is skinny. (Deloitte)

Vegetation are scaling past pilots. Many producers are shifting from experiments to deployments that ship measurable output. (Rockwell Automation)

What’s getting automated: AI-driven predictive upkeep, automated alerts, situation monitoring, spare-parts planning.

Why in 2026:

- Downtime is the common enemy. Predictive upkeep retains legacy tools viable whereas crops modernize regularly.

AI maturity is rising quick. Producers are broadly investing in AI/ML and more and more utilizing it to anticipate failures and schedule upkeep intelligently. (NIST)

What’s getting automated: AI-assisted manufacturing scheduling, automated quoting, dynamic stock selections.

Why in 2026:

- Uncertainty calls for adaptability. Tariffs, demand swings, provider volatility — crops want schedules that may re-optimize shortly. (Reuters)

- AI is shifting upstream. IDC predicts a big share of producers will improve scheduling with AI to allow extra autonomous operations. (IDC Weblog)

Throughout all these areas, one theme stands out:

Producers are automating what could be deployed shortly, owned by the workforce, and tailored to actual ground situations.

That’s why we see:

- modular cells over bespoke megaprojects,

- incremental automation over “rip and change,”

- and methods that operators can run confidently with out a PhD.

It’s additionally why workforce coaching and adoption have gotten the make-or-break issue. Even one of the best tech stalls with out individuals who can personal it. (Deloitte)

If you happen to’re planning your subsequent automation step, take a cue from what’s successful throughout the business:

- Begin the place the method is secure and the ache is apparent (end-of-line is the basic instance).

- Prioritize time-to-value over good long-range specs.

- Design for variability, not the best drawing.

- Construct operator possession early so the system scales as an alternative of stalling.

In 2026, automation isn’t about chasing essentially the most futuristic manufacturing unit.

It’s about constructing a Lean, versatile, resilient one, one step at a time.

If you wish to see whether or not palletizing automation is sensible on your facility, begin with the Palletizing Match Instrument — a fast, interactive technique to see if Lean Palletizing is the appropriate match on your line.