When producers take into consideration automating end-of-line operations, one query nearly all the time comes first: What does a palletizing resolution actually value?

The brief reply: it relies upon. The total reply: it’s not only a value; it’s a strategic funding in effectivity, consistency, and scalability.

At Robotiq, we’ve redefined what automation means for the manufacturing unit ground. By means of The Lean Palletizing Expertise, we assist producers transfer from guide to automated cobot palletizing with digital readability, production-ready pace, and modular scalability.

The larger image behind automation prices

Automation prices aren’t solely about {hardware}. They’re about time, complexity, and the way shortly you begin seeing outcomes.

Producers are sometimes compelled to decide on between two extremes:

- Inflexible pre-packaged techniques that may’t adapt to altering wants.

- Customized-built tasks that require heavy engineering and lengthy timelines.

Neither choice delivers the flexibleness or predictability that trendy manufacturing calls for. That’s why Robotiq affords two clear paths inside one unified expertise: PAL Prepared and PAL Sequence. However extra on that later. Let’s take a better take a look at total prices and a few concerns to bear in mind for {custom} options first.

Cobot System Prices: What’s Included?

Whenever you’re budgeting for automation, it’s necessary to acknowledge that the cobot arm is just one a part of the equation. To really get worth from the cobot, you’ll want extra parts, together with:

- Finish-Effector: That is the a part of the system that interacts with the product, similar to a gripper or suction cup, and its value varies relying on the precise job.

- Integration & Setup: Relying in your manufacturing line, you could want to switch current techniques (conveyors, air techniques, electrical infrastructure) to accommodate the cobot.

- Software program & Programming: A cobot would possibly require {custom} programming to operate in your particular setting, or, in some circumstances, you could want a specialised interface to assist the cobot work together together with your current techniques.

In the event you’re choosing a turnkey system the place the whole lot is pre-packaged and able to go, the price of a cobot system might be fairly affordable.

Nevertheless, in case your utility requires a extra custom-made resolution, the price can escalate shortly. In these circumstances, the price of engineering experience and the time required to create a tailor-made system can drive the overall value a lot larger.

Customized Options Issues

One of many largest elements that may enhance the price of a cobot system is {custom} engineering. In case you have a posh job that requires particular tooling or specialised modifications to your manufacturing line, you’ll have to put money into engineers to design and implement the answer.

Engineering expertise, significantly these skilled with automation techniques, is in excessive demand and might come at a premium. Customized options additionally are inclined to have longer lead occasions, that means you’ll have to plan forward for the potential delays in getting your system up and operating. Moreover, {custom} techniques would possibly face reliability challenges since they typically incorporate distinctive parts that haven’t been mass-produced or completely examined over time.

That being stated, a {custom} resolution could also be crucial for sure duties, and in these circumstances, the elevated funding might yield useful enhancements in effectivity and productiveness.

Nevertheless, in case your job is comparatively easy, an off-the-shelf system can do the job successfully whereas additionally retaining prices down.

PAL Prepared, production-ready from day one

As talked about earlier, producers are sometimes compelled to decide on between two extremes: inflexible pre-packaged techniques that may’t adapt to manufacturing modifications and custom-built tasks that require heavy engineering and lengthy timelines.

PAL Prepared and PAL Sequence supply a 3rd choice.

PAL Prepared is a absolutely assembled and production-ready palletizing cell—able to run on-site the second it reaches your facility.

It’s constructed for producers who need outcomes instantly, with out the complications of design phases or programming delays.

Key options embody:

- Sensible Infeed – mechanically delivers bins on the proper time and place.

- Mobility options – transfer between strains or clear ground area in minutes.

- Constructed-in security scanners – guarantee safety with out cumbersome fencing.

- PowerPick Multi Vacuum Gripper – handles product modifications with zero changeovers.

With PAL Prepared, you possibly can begin palletizing on day one and attain ROI sooner by means of predictable efficiency and minimal downtime.

PAL Sequence, modular palletizing that grows with you

For services that want extra flexibility, PAL Sequence affords a modular method constructed on Robotiq’s normal PE and AX Sequence fashions.

You may configure your system to match your utility—whether or not it’s including new SKUs, altering field dimensions, or increasing to a number of strains.

Each PAL Sequence cell shares the identical:

- Operator interface and software program.

- Digital instruments for design and validation.

- Lean Robotics logic for constant outcomes throughout all websites.

Which means whenever you develop, you don’t begin over; you scale throughout the similar dependable expertise.

The Lean Palletizing Expertise

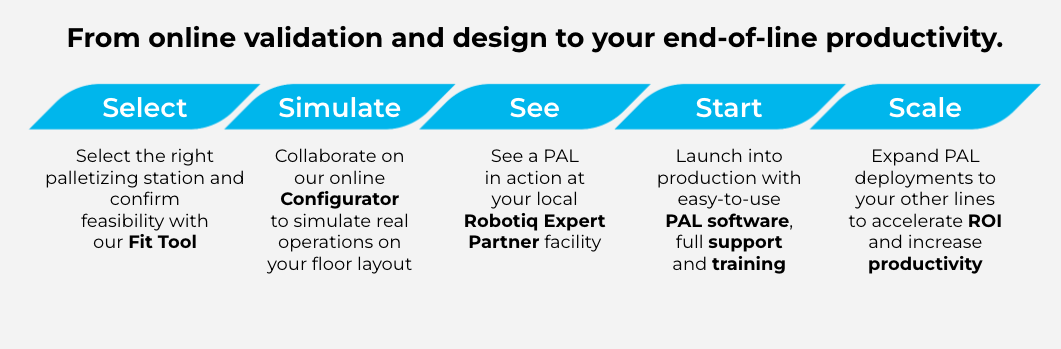

Each PAL Prepared and PAL Sequence are a part of The Lean Palletizing Expertise—a structured, five-step journey that transforms automation from complicated tasks right into a repeatable course of.

- Choose – Determine the precise alternative utilizing the Palletizing Match Software.

- Simulate – Validate your structure on-line with a full 3D simulation.

- See – Go to a Robotiq Skilled Associate to see PAL in motion.

- Begin – Launch into manufacturing with skilled assist and coaching.

- Scale – Increase to different strains or services for higher effectivity and ROI.

This digital-to-physical path turns uncertainty into readability and helps producers begin quick and scale with confidence.

ROI you possibly can measure — and the price of ready

Return on Funding (ROI) isn’t nearly what you spend; it’s about how shortly you recuperate it.

PAL Prepared prospects usually see ROI in 1-2 years, because of diminished setup time, constant uptime, and simplified upkeep.

However the value of inaction is usually larger: continued labor shortages, security dangers, and misplaced productiveness. Ready to automate means falling behind opponents who’re already reaping the rewards of automation.

The Hidden Advantages of Cobot Automation

Past the apparent monetary advantages, cobots additionally supply intangible benefits that may have a major affect on your corporation. These embody:

- Decreased Ergonomic Dangers: Cobot palletizers can tackle repetitive, bodily demanding duties, lowering the chance of harm in your employees and bettering office security.

- Worker Morale & Retention: By automating repetitive duties, you permit your workers to deal with higher-value work, which may enhance job satisfaction and morale.

- Flexibility and Scalability: Cobot techniques are extremely versatile and might simply be reprogrammed for brand spanking new duties or scaled to satisfy elevated demand. This makes them superb for companies that have to adapt shortly to altering market circumstances.

- Enhanced Buyer Notion: Many companies discover that prospects admire seeing automation in motion, which indicators innovation and a forward-thinking method.

See your ROI before you purchase

So, will Lean Palletizing be cost-effective in your manufacturing unit? Earlier than committing, know precisely what automation can ship in your manufacturing line(s).

👉 Attempt the Robotiq Palletizing Match Software to obtain:

- A {custom} 3D simulation of your palletizing cell.

- ROI and payback calculations primarily based in your manufacturing knowledge.

- A downloadable report you possibly can share together with your group.

Begin quick. Scale with confidence.